Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine

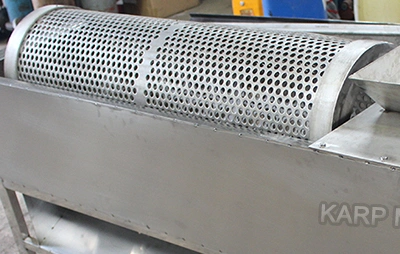

Drum Sieve made of carbon steel, single layer with 2 outlets

1-layer Trommel screen sifter machine

1-layer Trommel screen sifter machine

Trommel screen with screw conveyor

Different type of Trommel screen

Working principle:

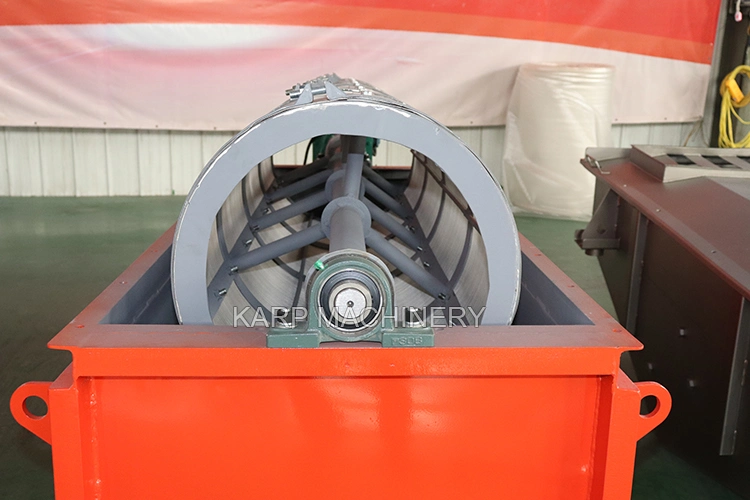

Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine is cylindrical drum, which is inclined and installed on the frame. The geared motor is connected to the drum device through a coupling, and the driving drum will rotate around the axis direction. When the materials enter the tilting and rotating drum device, the materials on the screen surface are overturned and rolled so that the fine materials are discharged from the discharge port at the bottom of the drum of trommel screen, while the large materials are discharged from the discharge port at the tail of the drum. As the materials in the drum turn and roll constantly, the materials stuck in the screen can be ejected to prevent the sieve blocking.

1. Optional sieve type: | Woven mesh | Round hole perforated sieve | Bar type sieve |

2. Shaft or shaftless type: | Shaft type | Shaftless type |

3. Optional material: | Carbon steel | Stainless steel |

4. With wheels or without wheels: | With wheels | Without wheels |

Our advantages:

1. Optional automatic cleaning brush on the top of trommel screen to avoid the blockage.

2. Smooth operation, low noise.

3. High screening efficiency, large screening capacity.

4. Simple structure, easy maintenance.

5. Sieve drum can be closed, easy to close the dust collection.

6. Convenient maintenance, the upper hood is removable.

Our Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine can be used in chemical, coking plant, mine, power plant, building materials, metallurgy and other industries, commonly used in medium and fine material classification screening, in order to improve the quality of materials.

1. Chemical industry: sifting calcium oxide, compost, fertilizer, ammonium sulfate, potash, etc.

2. Quarry: suitable for screening and classifying gravel, clay, soil, mountain meal, sand, etc.

3. Coal Industry: suitable for screening and classifying lump coal, coal dust, coal washing, bottom ash, etc.

4. Abrasive material and ceramic industry: building sand, mica, alumina, silica sand, abrasive, refractory material, etc.

5. Metallurgy and mining industry: quartz sand, sand, ore, titanium oxide, zinc oxide, gold screening and washing, etc.

6. Mechanical industry: casting sand, charcoal, powder metallurgy, electromagnetic material and metal powder, etc.

7. Recycling industry: solid waste, scrap tires, plastic, etc.

Customer on-site pictures:

Packing for Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine.

Packing for Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine.

Outside package: standard export wood box.

Inner package: stretch film for machine, accessories in carton.

Optional shipping type: Support Sea freight · Land freight

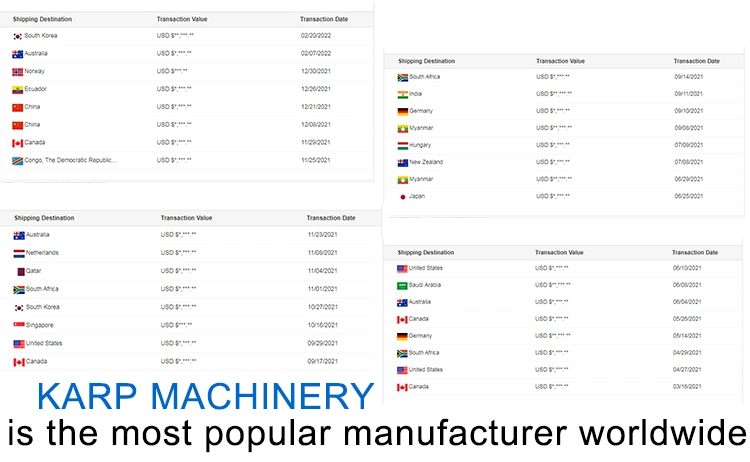

Xinxiang KARP Machinery Equipment CO.,Ltd is one of the leading manufacturers of vibrating screen sifter, conveying machines, feeding machines, elevating machines and related products with 11-year designing and manufacturing experiences.

We are committed to solve all screening and conveying problems of bulk materials. Depending on the quality as the life of enterprise, we have won our customers' identity with professional solution, high quality products, perfect service. Our main products are vibrating screen, round separator, rectangular separator, drum screen (Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine), gyratory screen, tumbler screen, screw conveyor, belt conveyor, vacuum conveyor, bag unloader, vibration table, standard laboratory inspection sieve, bucket elevator, vibration elevator, vibration motor, vibrating conveyor, feeding machine and related parts.

The proper selection of the Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine depends on the material, mesh size, output required, method of input, abrasiveness of the material etc:

1. Material : _____

2. Moisture:_____%

3. Capacity: :________kg/ hour

4. Screen layer:_______

5. Screen mesh size:______ mesh . ______ mesh. ______ mesh

6. Voltage:______V, Frequency:______HZ, 3 phase

7. SS304/316L stainless steel or carbon steel?

Q: How long for the manufacturing time?

A: 10-15 working days.

Q: How long for warranty time?

A: 13 months from the shipping date.

Q: Can your engineer come to the construction site to guide the installation?

A: Yes, we can arrange our engineer to guide your installation.

Q: How can we guarantee the quality?

A: We provide a set of the sealing parts and installation tools of vibrating screen with our machine for free. And one year warranty period.

Q: What can you buy from us?

A: We provide one stop solution for powder materials: screening, conveying, weighing, mixing, packing and dumping.

1-layer Trommel screen sifter machine

1-layer Trommel screen sifter machine

Packing for Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine.

Packing for Trommel Compost Sifter Saw Dust Clove Drum Screen Sieving Machine.